Inspired by materials found in oyster and balloon shells, Princeton University researchers have created a new, highly versatile cement composition.

This design mimics the brick-and-mortar structure of the shell, increasing durability by inducing inelastic deformation and hierarchical strengthening.

The newly developed material is 19 times more flexible, can be stretched without breaking and is 17 times more resistant to cracking than ordinary cement.

According to the team, the results could ultimately improve crack resistance in various brittle ceramic materials, such as porcelain and concrete.

Structural strength inspired by nature

Unlike materials such as glass, wood and steel, cement is brittle and not very flexible without fibers and reinforcements. These drawbacks limit its use in structural applications.

Several methods have been tried to improve the low fracture toughness and ductility of cementitious materials by adding polymeric, glass or metallic reinforcements to cementitious compositions. According to the researchers, these approaches result in only small increases (about a one-time increase) in energy absorption and fracture toughness, mostly at the cost of directly changing the materials’ microstructure.

The Princeton team found that alternating thin layers of polymer and patterned cement paste can greatly improve ductility—the ability to bend without breaking.

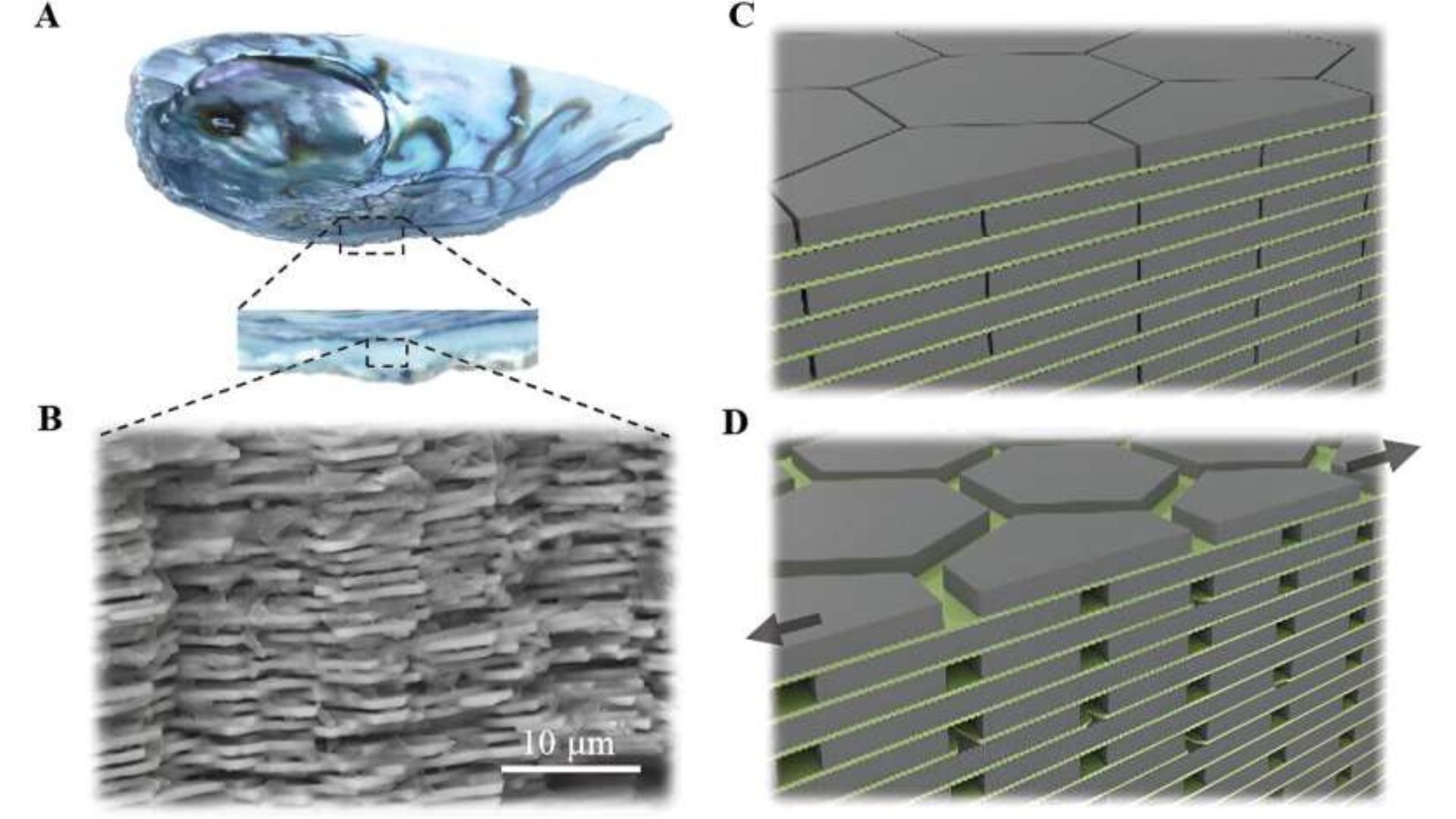

The group was inspired for their work in creating materials from biology. In this case, the group created a compound modeled after nacre, a natural substance that can be found inside specific shells.

According to the researchers, nacre consists of hexagonal-shaped tablets of the hard mineral aragonite held together at the microscopic level by a soft biopolymer. Its 3D brick-and-mortar structure allows the tablets to slide and the biopolymer to deform, absorbing energy and increasing durability.

These mechanisms, along with nano-asperities and intercalation of tablets, make nacre resilient despite the brittle components.

“This synergy between hard and soft components is fundamental to nacre’s exceptional mechanical properties,” said Shashank Gupta, a graduate student in Princeton University’s Department of Civil and Environmental Engineering, in a statement.

New cement composites

The Princeton researchers used common construction supplies like Portland cement paste and a small amount of polymer to create new nacre-inspired composites.

Layers of cement paste sheets were alternated with polyvinyl siloxane, a highly flexible polymer. By alternating thin layers of polymer with sheets of cement paste, the researchers were able to produce small, multi-layer beams.

Then, to evaluate the resistance to cracking (also known as breaking strength), each of these beams was subjected to a three-point bending test.

The researchers created three types of beams: the first with alternating layers of cement paste and thin polymer sheets; the second with laser-etched hexagonal grooves on cement sheets stacked with polymer layers; and the third with fully separated hexagonal cement tablets bonded with polymer, imitating nacre. These were compared to a solid cast cement paste reference.

The results showed that these compounds mimic the sliding and energy absorption mechanisms of the nacre tablet. The split nacre composites had 17 times greater fracture toughness and 1791 percent increased ductility compared to solid cement.

Strengthening mechanisms include interlayer deformation, torsional crack propagation, and tablet sliding. Using laser processing and elastomeric layers, this approach significantly improves the mechanical properties of cement while reducing the risks of failure.

According to the researchers, future work could explore different soft materials for resilient infrastructure, improve groove shapes for better defect integration, and simplify manufacturing methods using integrated lamination-laser processes or additive manufacturing for more advanced applications. extensive infrastructure.

Details of the team’s research were published in the journal Advanced functional materials.

ABOUT THE EDITOR

Jijo Malayil Jijo is an automotive and business journalist based in India. Armed with a BA in History (Hons) from St. John’s College. Stephen, University of Delhi, and a PG degree in Journalism from the Indian Institute of Mass Communication, Delhi, he has worked for news agencies, national newspapers and automotive magazines. In his spare time, he enjoys going off-road, engaging in political discussions, traveling and learning languages.